上海質偉企業管理咨詢有限公司

地址:上海市浦東新區益江路299弄35號103室

質偉認證咨詢(杭州)有限公司

地址:浙江省杭州市濱江區火炬大道581號三維大廈A座805室

聯系人:劉先生 手機:16621385165

電話:021-53391362

郵箱:lw@zwemc.com

鋁合金材料工廠認可時,多家船級社均提出了金相組織與耐腐蝕性能的相關性試驗要求,但很多制造商的鋁合金常規試驗中未開展此類相關性分析,本文根據咨詢經驗,為各位相關用戶提供一個落地方案。下面就DNVGL船級社的要求開展分析及落地。

第一節:DNVGL認可要求

ReLationship between microstructure and resistance to corrosion(if applicable)

— for plates that require exfoliation and inter-granular corrosion the manufacturer shall establish the relationship between microstructure and resistance to corrosion

— a reference photomicrograph taken at 500x, under the conditions specified in ASTM B928, 9.4.1 shall be established for each of the alloys for each of the applicable tempers and for each thickness ranges as

relevant. The reference photographs shall be taken from samples which have exhibited no evidence of exfoliation corrosion and a pitting rating of PB or better, when subjected to the test described in ASTM G66 (ASSET). The samples shall also have exhibited resistance to inter-granular corrosion at a mass loss no greater than 15 mg/cm2, when subjected to the test described in ASTM G67

— upon satisfactory establishment of the relationship between microstructure and resistance to corrosion, the reference photomicrographs and the results of the corrosion tests shall be approved by the Society

— production practices shall not be changed after approval of the reference micrographs.

第二節:落地措施

一、建立金相組織與耐腐蝕性能相關作業文件

當制造商日常開展了5083,5383,5059,5086,5456的H116或H321狀態下的金相組織分析,晶間腐蝕及剝落腐蝕試驗時,可以根據這些歷史數據建立相應的作業指導書,建立每種牌號、不同制造方式(冷軋/熱軋)及狀態(H116,H321)產品的金相組織與耐腐蝕性對應關系。

二、建立金相組織與耐腐蝕性能分析報告

本文推薦使用該種方式,適用于建立數據庫不完善的廣大鋁合金制造商:

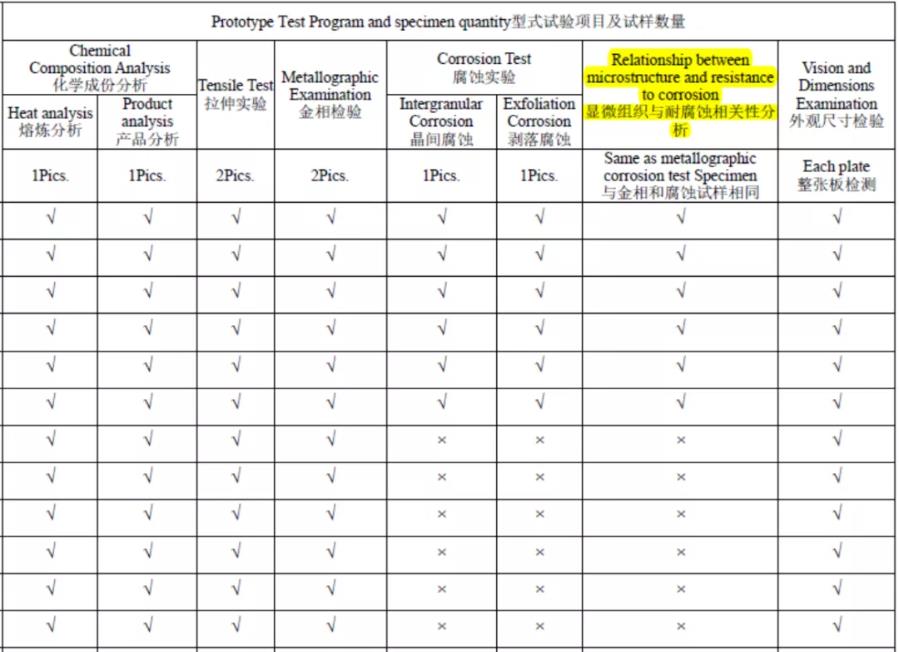

1、在提交型式試驗大綱時,在5083,5383,5059,5086,5456的H116或H321狀態產品的試驗項目下提報一個金相組織與耐腐蝕性能分析項目:

2、規定金相分析、晶間腐蝕、剝落腐蝕試驗要求;

Metallographic examination金相分析

Specimen shall be sampled at the mid-wall thickness of the test block. The test block shall be made from mid width of the product, at one end of plates.

金相試樣應取自1/2厚度。試樣應從板材一端的1/2寬度位置截取。

For rolled plates: a longitudinal section perpendicular to the rolled surface shall be prepared. The microstructure shall be compared to the reference photomicrograph of acceptable material.

對于軋制板材,試樣的縱向界面垂直于板材軋制面。顯微組織照片應在報告中體現,并能作為材料接收準則的依據。

High quality photomicrographs showing the microstructure at 100x and 500x magnification shall be prepared with a brief description. The magnification shall be indicated on the micrographs by a line symbol, e.g. with length of 0.5 mm or 100 μm. Arrows or letters may be used to identify features referred to in the report.

100x和500x的清晰照片和簡單的描述需要在報告中體現。照片中包含線性標尺符號,如0.5 mm或100 μm長度的標尺。為了識別特征箭頭或字母可以在報告中使用。

IntergranularCorrosion晶間腐蝕

1 Rolled 5000 series alloys of grade 5083, 5383, 5456 and 5086 in the H116 and H321 tempers intended for use in marine hull construction or in marine applications where frequent direct contact with seawater is expected shall be tested with respect to inter-granular corrosion resistance.用于船體機構或海工應用于平凡接觸海水的熱處理狀態H116, H321的5083, 5383, 5456和5086應進行晶間腐蝕試驗。

2 Measure all three dimensions to the nearest 0.02 mm, and calculate the total surface area.測量所有的三個尺寸精確到0.02mm,并計算總表面積。

3 Immerse the specimens in 5 % NaOH solution at 80°C for 1 min followed by a water rinse, a 30-s immersion in HNO3(desmut), and a water rinse. Allow the specimens to air dry. Do not wipe dry with a cloth or paper towel.將試樣浸入到80℃,5%NaOH溶液中1分鐘,然后用水沖洗。再將試樣浸入到硝酸溶液中30秒,然后用水沖洗。將試樣在空氣中晾干。不允許用布或紙巾將試樣擦干。

4 Weigh the specimens to no more than±1.0 mg, preferably 0.1 mg.稱量試樣至兩次不超過±1.0 mg,精確至0.1mg。

5 Use sufficient test solution to fully immerse the specimens and constitute a volume to specimen surface area ratio of at least 30 L/m2. Maintain the test solution temperature at 30±0.1°C. Immerse the specimens in the test solution for 24 h.將使用完全浸入到試驗溶液中。溶液體積與試樣表面積比率不小于30L/m2。保持試驗溶液溫度為30±0.1°C。浸蝕時間為24h。

6 Remove the specimens, and rinse with water while brushing with a stiff plastic bristle brush, for example, a toothbrush, to remove all adhering particles. Allow to air dry.將試樣取出用水沖洗并用硬所料毛刷刷洗,除去所有附著微粒,然后在空氣中晾干。

7 Weigh the specimens and determine mass losses. In case of testing in accordance with ASTM G67 the mass loss shall not exceed 15 mg/cm2.稱量試樣重量并計算重量損失率。按ASTM G67試驗的重量損失率不大于15 mg/cm2.

Exfoliation Corrosion剝落腐蝕

1 Rolled 5000 series alloys of grade 5083, 5383, 5456 and 5086 in the H116 and H321 tempers intended for use in marine hull construction or in marine applications where frequent direct contact with seawater is expected shall be tested with respect to exfoliation corrosion resistance.用于船體機構或海工應用于平凡接觸海水的熱處理狀態H116, H321的5083, 5383, 5456和5086應進行剝落腐蝕試驗。

2 Degrease the specimens with a suitable solvent. After degreasing, prepare specimens as follows: Etch 1 min in 5 % by weight sodium hydroxide solution at 80°C, rinse in water, desmut 30 s in concentrated nitric acid at room temperature, rinse with distilled or deionized water, air dry.用適當的溶劑給試樣脫脂。脫脂后,準備樣本如下:用重量百分含量在5%的氫氧化鈉溶液在80°C蝕洗1分鐘,清水沖洗,再在室溫下的濃硝酸中30s,用蒸餾或去離子水,洗凈晾干。

3 Use fresh solution at the start of each test.每次實驗前更換新的溶液。

4 Immerse the specimens vertically with the top edge of the specimens at least 25 mm (1 in.) below the surface of the solution and the bottom edge at least 25 mm above the bottom of the container.把試樣完全浸沒在試驗溶液中,溶液面在垂直方向上至少在試樣上表面25mm以上,試樣下表面離容器底部25mm。

5 Immerse the specimens in the test solution continuously for 24 h.把試樣浸沒在試驗溶液中24h。

6Rinse the specimens gently in running tap water immediately after removal from the solution, then soak in concentrated nitric acid at room temperature until they appear clean, again rinse in water, and air dry.但把試樣從試驗溶液中拿出來后在流動的水中沖洗,然后放在洪硝酸中清洗至表面干凈位置,然后用水沖洗,空干。

7 Air-blast drying is to be avoided in order to prevent mechanical removal of exfoliated metal.用吹風機吹干試樣以防止機械性的操作到時剝脫金屬的掉落。

8 Accepted test standards are ASTM G66 (ASSET). The indices for exfoliation corrosion shall be within the level EA and those for crevice corrosion rate shall be within PB according to ASTM G66.試驗標準為ASTM G66 (ASSET),剝落腐蝕的指標小于EA級,縫隙腐蝕率在PB級以內。。

3、建立金相組織與耐腐蝕性分析報告。

根據規定的牌號及狀態下型式試驗產品的金相分析結果、晶間腐蝕及剝落腐蝕試驗結果建立如下分析報告。

4、規定在工藝條件不變的情況下,后期產品檢驗可以用金相分析代替耐腐蝕性能試驗。